Our Capabilities

Product Realization Process

-

Production Part Approval Process (PPAP)

-

Failure Mode Effects Analysis (FMEA)

-

Control Plan (CP)

-

Measurement System Analysis (MSA)

Design

-

Define

We conduct thorough conversations to explore your application and need

-

Explore

We leverage our expertise and knowledge to offer options for enhancements and a suite of solutions

-

Innovate

Together we determine the best solution and then use Catia and AutoCad Inventor to help you visualize our design enhancements and recommendation

-

Model

We manufacture a single piece to assess, modify if necessary, and prepare for mass production

-

Build

We can manufacture a quality product in a wide range of volumes

-

Assess

We can review current products to identify opportunities for improvement

-

Improve

We use VAVE (value added/ value engineered) to provide enhancements

Our affiliation with G.S. ELECTECH in Japan, also provides us exclusive access to extend our resources for the design and development of new parts for OEMs and Tier 1 manufacturers.

Lab

We complete crimp analysis testing for every crimp to ensure the highest quality, longest lasting electrical connection. In house testing including USCAR, IPC validation and testing requirements to OEM validation. Our lab capabilities are enhanced by exclusive access to a Technical Center in Japan, qualified to conduct any testing required by OEM manufacturers, because of our affiliation with G.S. ELECTECH.

Prototyping

Our team provides customers a variety of options to view their products prior to production. We have a designated area within the Findlay operations that enables us to manufacture prototypes, production samples and trial parts for customer review and evaluation. Our procurement team can source limited component quantities, our engineering team can produce a 3D rendering of the product and our operations associates can provide test harnesses as an interface cable between customer test devices and GSW harnesses.

Tooling

We make nearly all of the tooling required to assemble and test our assemblies in-house. This expertise enables us to control the quality of the tooling and quickly manage necessary adjustments that avoids delays.

Materials Sourcing

Our procurement experts have a global sourcing network that spans Asia, Europe and the Americas. They are well-versed in sourcing difficult to find components and identify the most suitable parts to meet the needs of our customers.

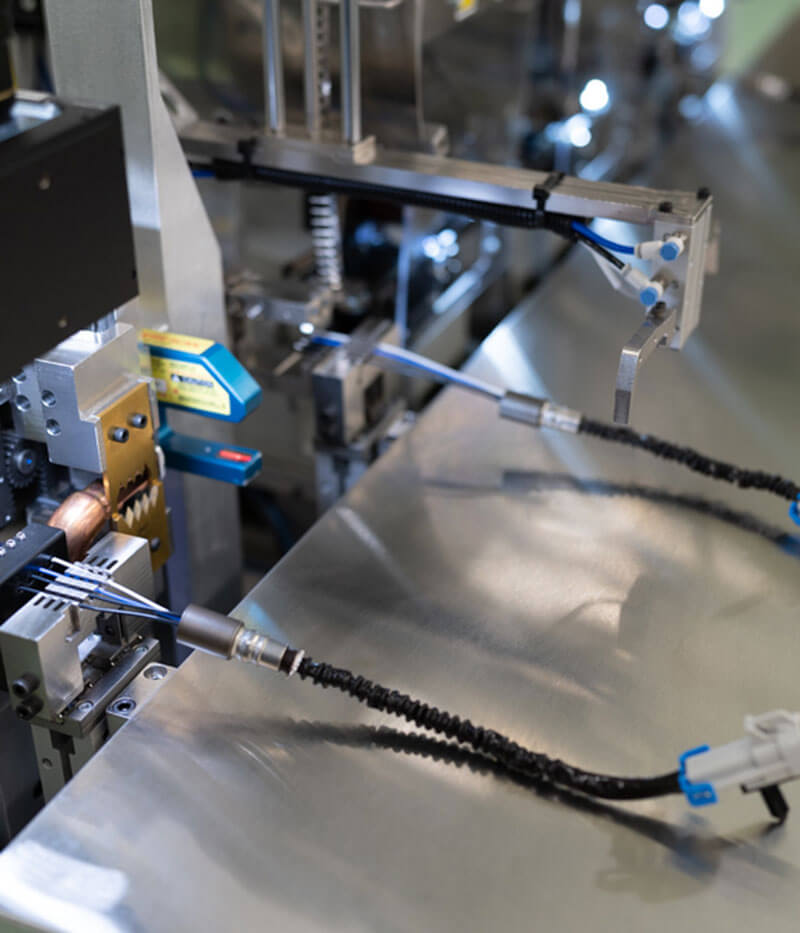

Manufacturing

We make nearly all of the tooling required to assemble and test our assemblies in-house. This expertise enables us to control the quality of the tooling and quickly manage necessary adjustments that avoids delays.

Testing

All the harnesses we manufacture are 100% tested for continuity and functionality. Our testing regimen, which includes Dynalab and Cirrus wire testers, ensures the quality of every assembly.

Aftermarket

All the harnesses we manufacture are 100% tested for continuity and functionality. Our testing regimen, which includes Dynalab and Cirrus wire testers, ensures the quality of every assembly.

Innovation & Technology

Data-driven Approach

-

Ensure Quality

We can predict and identify potential quality concerns and root causes long before products leave our facilities.

-

Optimize Resources

Our business intelligence strategy allows our team members to gain insights more efficiently to add value and identify obstacles before they become unneeded costs.

-

Increase Performance

With the use of cutting-edge technology, we consistently automate non-value-added activities throughout our organization.

-

Optimize Supply Chains

We capably and proficiently identify profitable opportunities despite the complex data associated with an international supply chain.

Our

Certifications

-

GSW Ohio

Certification Number Issue Date IATF 16949 C0097782-TS9 27-Jun-24 ISO 9001:2015 C0097782-IS5 27-Jun-24 ISO 14001:2015 C0097782-EM7 28-Jul-21 -

Reynosa

Certification Number Issue Date IATF 16949 C0097783-TS2-C0097782 15-Sep-21 ISO 14001:2015 C0097783-EM6 27-Aug-21 -

GTO

Certification Number Issue Date IATF 16949 C0232566-TS5-C0097782 6-Jul-23 ISO 9001:2015 C0232566-IS5 6-Jul-23 ISO 14001:2015 C0232566-EM3 5-Jul-24

Let’s get started.

Beginning with our first conversation, we are creating solutions to bring your idea to reality. Our collaborative approach, design expertise, engineering capabilities, and quality manufacturing makes us your ideal partner for wire harnesses.

For more info about GSW,

give us a call.

419.423.7111